Insert new photo

Tired of hand dosing pigment? Install a DCS dispenser!

DCS has been a leading provider of automation equipment in the construction space since the mid-1990’s. With over 30 years of experience, DCS’ systems are proven to increase efficiency, cleanliness and batch-to-batch consistency.

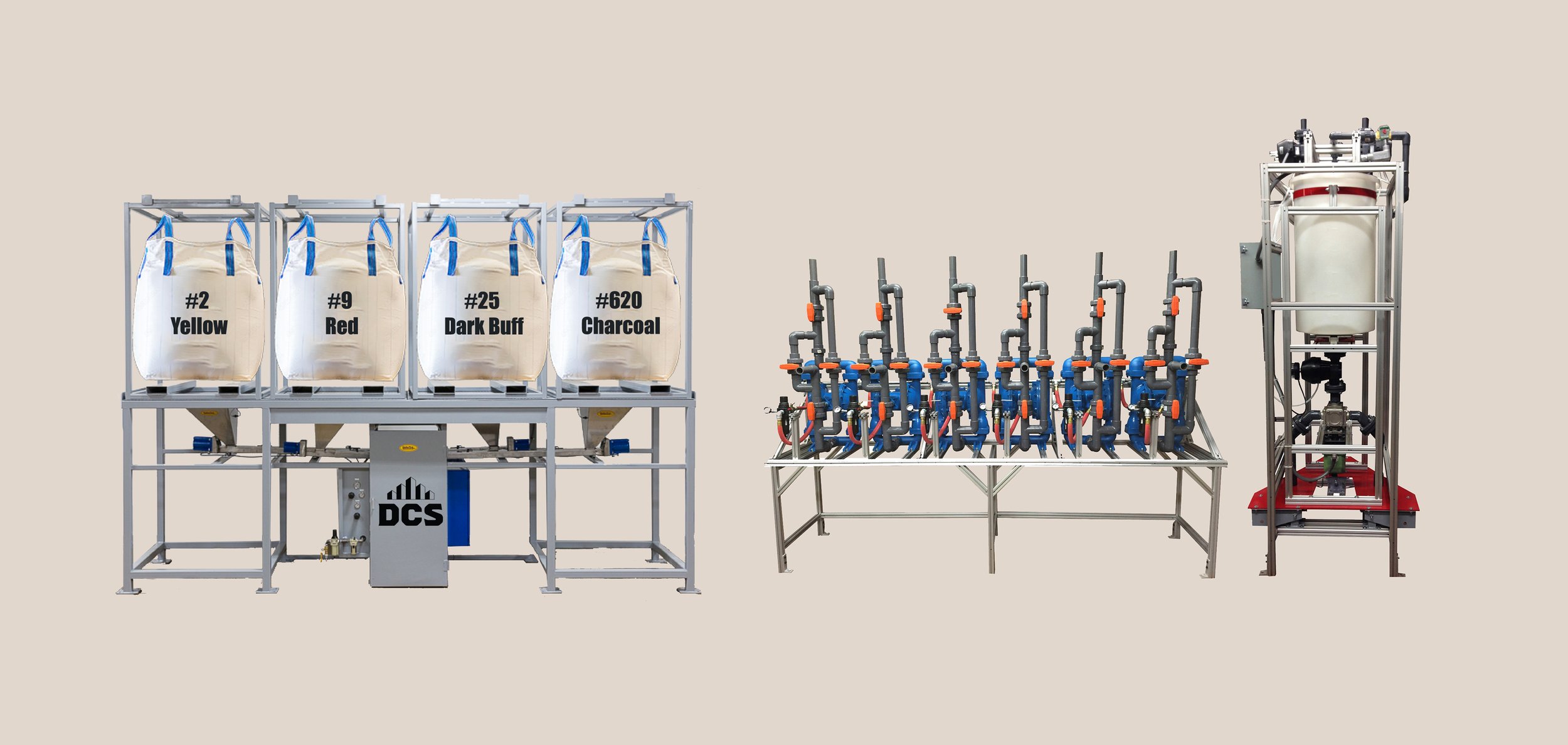

DCS Base Color System

Whether utilizing a liquid or granular color dispenser, both systems utilize DCS’ base color system. Using either four of five base colors, this system enables producers to make a wide-array of colors while only having to stock those base pigments. Blends of all these colors are automatically weighed and dispensed into the mix, removing the possibility of employee error and minimizing batch to batch variation. The best part: at the end of a job, there’s nothing left over. Those base pigments can be utilized on the next job to create a totally unique look and feel to all your projects.

“The use of DCS’ liquid pigment system has given us full flexibility with our architectural mixes. With the use of nine different pumps, we have the ability to run the five base colors and also have four additional pumps for preblended colors. Not only has DCS provided us with the best liquid color in the industry, they have also helped tremendously in our batch plants - both upgrading existing and new construction. The seamless communication between their weigh vessels and the batch plant control system has made the process of weighing dye accurately a non-issue. The knowledge, dedication and customer service at DCS is the best you can find in the industry.”

Matt Everding // Wells Concrete

Liquid Dispensing Systems

Our state-of-the-art liquid color dispensing equipment will automate pigment addition at your plant, saving labor and reducing the possibility of error. Whether you’re producing ready-mixed concrete, precast wall panels, manufactured stone veneer, cast stone, or another concrete product, our dispensing equipment will accurately weigh exactly what you need for each batch.

All DCS dispensers are designed with two basic components—a pump rack and weigh vessel. The pump rack moves material from storage to the vessel, and the vessel weighs the proper amount of each material and discharges it into your mixer. This process is followed by a clean water rinse. Gravity discharge from the weigh vessel ensures that all product weighed is discharged into the mixer.

Granular Dispensing Systems

Each machine is equipped with four supersacks of DCS granular color including Synthetic Red, Yellow, and Black as well as Natural Buff to allow the widest range of possible end colors available in the market.

Highly accurate weighing equipment and hundreds of saved recipes are included in the standard control package.

“Granular dye has been a gamechanger for Gage when it comes to color consistency and water-to-cement ratio control. We have had zero panel to panel color issues on site since the change.”

Mike Hoxter // Gage Brothers

LIQUID COLOR

LABORATORY & SAMPLE SERVICES

GRANULAR